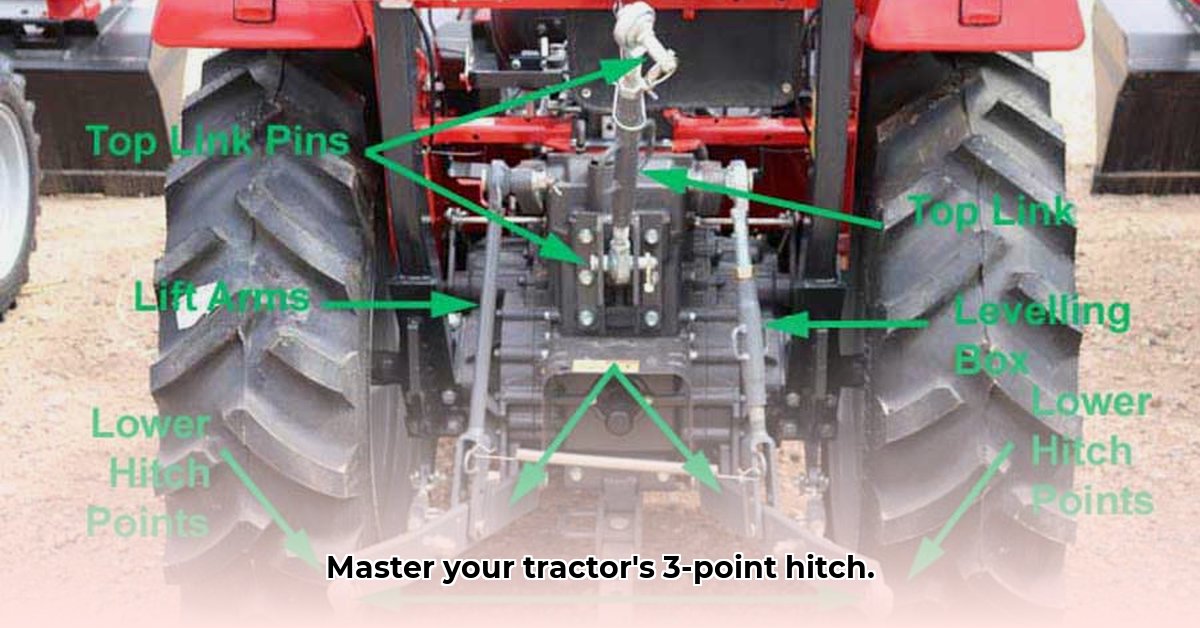

Understanding Your Tractor's 3-Point Hitch System

Your tractor's 3-point hitch is a crucial system connecting your tractor to various implements like plows, seeders, and tillers. This system, consisting of two lower arms and a top link, forms a triangle that allows for controlled implement movement. The 3-point hitch pins are the critical connectors, ensuring secure attachment and smooth operation. Understanding this system is vital for efficient and sustainable farming. Different tractor models may have slight variations in their hitch systems; always consult your tractor's manual for specific details. This understanding is crucial for correctly selecting and using 3-point hitch pins, ensuring both safety and efficiency. Did you know that a properly functioning 3-point hitch system can significantly reduce soil compaction, leading to healthier soil and increased yields? For more in-depth information, check out this helpful resource: 3-point hitch guide.

Types of 3-Point Hitch Pins

Several types of 3-point hitch pins cater to different needs and applications. Choosing the right pin is crucial for both safety and efficiency. The material of the pin also significantly influences its lifespan. Here's a breakdown of common pin types:

Standard Pins: These are simple, robust pins suitable for general-purpose applications where frequent implement changes are not necessary. They provide a reliable and cost-effective solution for many tasks.

Clevis Pins: These pins feature a clevis (U-shaped fitting) at one end, allowing for quicker and easier implement connection and disconnection. This design saves time and effort, especially when switching between implements frequently.

Quick-Attach Pins: Designed for speed and efficiency, these pins usually incorporate a locking mechanism, enabling rapid implement changes. This is particularly beneficial during time-sensitive operations.

Material Matters: Pin material significantly impacts durability and longevity. Common materials include steel, hardened steel, and stainless steel. Hardened steel provides superior strength and wear resistance, extending the pin's lifespan. Stainless steel offers excellent corrosion resistance, making it ideal for wet or corrosive environments. The choice depends on the specific application and environmental conditions. A more durable pin might cost more initially, but its extended lifespan can lead to long-term cost savings. Choosing sustainable materials is also becoming increasingly important, so look for options with responsible sourcing and recyclability.

Selecting the Right Pin: A Step-by-Step Guide

Selecting the appropriate pin is critical for safe and efficient operation. Follow these steps to ensure you choose the correct pin for your needs:

Consult Your Tractor Manual: Your tractor's manual specifies the correct pin specifications for your model, ensuring compatibility and preventing potential damage.

Check Implement Specifications: The implement's manual will indicate the recommended pin size and type. Using the incorrect pin can lead to instability and potential safety hazards.

Consider Working Conditions: Wet or corrosive environments necessitate corrosion-resistant pins like stainless steel to prevent premature failure.

Prioritize Safety: Never compromise on safety. If unsure, select a slightly stronger pin rather than risking a weaker one. Remember, a failure can have serious consequences.

Installing and Using 3-Point Hitch Pins: Safety Precautions

Safe installation and use are paramount. Always follow these steps:

Align the Implement: Ensure the implement is perfectly aligned with the tractor's hitch before inserting the pin. Misalignment can damage both the implement and the tractor.

Insert the Pin Carefully: Guide the pin into the hitch, using a mallet only if necessary. Avoid excessive force. If insertion is difficult, there is likely a misalignment that needs to be corrected.

Secure the Pin: Ensure the pin is securely locked if it has a locking mechanism. Double-check for stability before operating the equipment.

Test the Connection: Before commencing work, perform a test run of the attached implement. This allows for the early detection and correction of any issues.

Maintenance and Troubleshooting: Extending Pin Lifespan

Regular inspection and maintenance significantly extend pin lifespan and prevent costly repairs.

Regular Inspection: Frequently inspect pins for bending, wear, or damage. Replace any damaged pins immediately. Ignoring damage can lead to catastrophic failure.

Lubrication: Periodic lubrication reduces friction and extends pin life. A light coating of suitable grease is generally sufficient.

Bent Pins: A bent pin indicates a misalignment during attachment. Inspect both the hitch and the implement to identify and correct the cause.

Worn Pins: Replace worn pins promptly to avoid implement detachment and potential accidents. Don't compromise safety.

Sustainability Considerations: Environmentally Responsible Farming

The choice of pin materials and disposal methods influence the environmental impact of farming.

Durable Pins: Choosing high-quality pins reduces waste by extending their lifespan. This minimizes the need for frequent replacements, reducing material consumption and landfill waste.

Sustainable Materials: Opt for responsibly sourced materials whenever feasible. Look for suppliers that prioritize sustainability in their manufacturing processes.

Proper Disposal: Dispose of worn-out pins according to local regulations to reduce environmental harm. Explore recycling options where available.

By following these guidelines, you can ensure the efficient, safe, and sustainable use of 3-point hitch pins, contributing to a more productive and environmentally responsible farming operation. Remember, attention to detail pays off in the long run!